Description

Anti-slip Hexagonal Film Faced Plywood

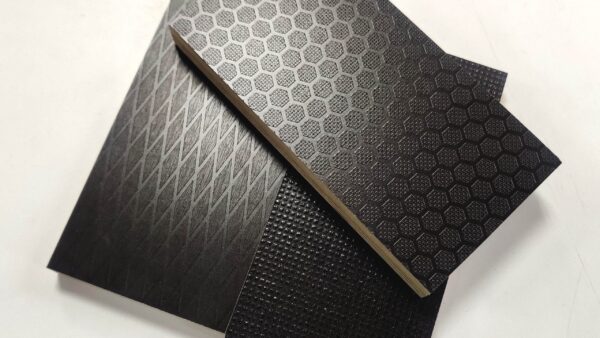

Anti-slip Hexagonal Film Faced Plywood is a new pattern of anti-slip film faced plywood that differs from wire-mesh anti-slip film faced plywood.

Anti-slip Hexagonal Film Faced Plywood has a cool pattern. Hexagonal shapes make up the convex portions of the Anti-slip FFP. However, the film is still brown, the same color as the brown film used for wire-mesh FFP.

Under high pressure and high temperature, hexagonal patterns are carved onto steel plates to create the anti-slip design. The manufacturing procedure is the same as for plywood with a wire-mesh film front.

Anti-slip Hexagonal Film Faced Plywood has superior anti-slip properties to hexagonal film faced plywood when comparing the anti-slip effects of the two patterns.

High-quality plywood called “film-faced birch plywood” is covered with resin paper that has been treated so that it hardens into a protective film during manufacturing. Since it is simple to mount and use, this type of Anti-slip Hexagonal Film Faced Plywood is frequently employed in construction and the manufacture of vehicles. It is popular for outdoor playground equipment and kids’ furniture since it is simple to color.

A unique variety of plywood with a wear-resistant, waterproof film covered on both sides is called “film-faced plywood,” also referred to as “phenolic plywood.” The purpose of the film is to shield the plywood from damaging environmental elements and increase its useful life. Anti-slip Hexagonal Film Faced Plywood is also known as phenolic plywood because both of its sides are impregnated with phenolic resin to produce a stable, enduring, smooth, and water-resistant surface.

Anti-slip Hexagonal Film Faced Plywood with a solid core or birch/pine twin core plywood are both covered in a phenolic layer with patterns to prevent slippage. Film Faced with Slip Resistance Similar to conventional smooth phenolic film facing panels, plywood is created in a similar way, with the addition of applying a patterned, metallic press to the face to produce the desired design. This substance offers excellent walkway and commercial vehicle floor traction for bare feet.

This durable phenolic film overlay is chemically bonded to the surface of this external plywood’s slip-resistant surface. This layer’s surface is imprinted with an equilateral triangle pattern made up of hundreds of dark brown hexagonal raised spots that are roughly 10mm in diameter.

The panels’ raised hexagonal pattern gives them strong anti-slip capabilities in a variety of climatic situations, making them the perfect material for demanding flooring applications. The design gives the panels a surface that is not just non-slip but also very simple to maintain clean.

Anti-slip Hexagonal Film Faced Plywood Features

- Anti-slip surface: The hexagonally patterned film has high slip resistance, making it safe to use in environments where there is a risk of slipping, such as building sites, workplaces, and outdoor spaces.

- Sturdy: Birch plywood, which is prized for its strength and durability, is used to make hexagonal anti-slip film-faced plywood. Both heavy loads and wear and tear can be endured by it.

- Waterproof: The plywood has a waterproof covering applied to its surface, making it perfect for use in outdoor applications. It can tolerate being exposed to wetness and bad weather.

- Simple installation: Hexagonal anti-slip film-faced plywood is simple to set up and may be customized to the right size. It is hence a well-liked option for flooring and other construction-related uses.

- Versatile: The material can be applied to a variety of projects, including building floors, walls, roofs, and other structures. Both indoor and outdoor use are appropriate for it.

- Economical: Hexagonal anti-slip film-faced plywood is a cost-effective substitute for various types of building supplies. It is simple to use and can speed up and save on installation expenses.

Application

- Flooring: Anti-slip Hexagonal Film Faced Plywood is frequently used for flooring, especially in locations where slip resistance is crucial, like industrial sites, outdoor decks, and commercial kitchens.

- Industrial platforms: In industrial platforms with heavy loads and high traffic volumes, Anti-slip Hexagonal Film Faced Plywood is employed. Safer working conditions are provided by the anti-slip surface.

- Transportation: To offer a slip-resistant surface and safeguard the cargo, hexagonal anti-slip film-faced plywood is used in transportation applications such as truck floors and shipping containers.

- Scaffolding: To give workers who must stand on elevated platforms a safe working surface, scaffolding is made of hexagonal anti-slip film-faced plywood.

- Wall panels: To offer a sturdy and slip-resistant surface in high-traffic places, such as hospitals and schools, hexagonal anti-slip film-faced plywood is utilized in wall paneling applications.

- Roofs: To offer a slip-resistant surface for personnel who need to access the roof for maintenance and repair work, hexagonal anti-slip film-faced plywood is utilized in roof applications.

Environmental

Anti-slip Hexagonal Film Faced Plywood is a building material that is sustainable and eco-friendly and has a number of advantages over other materials. By deciding to use plywood for construction projects, we may lessen our environmental effect and create communities that are more sustainable.