Description

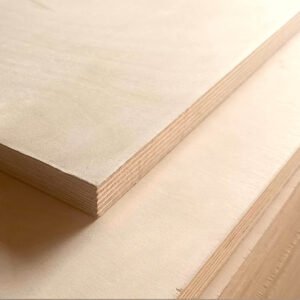

4’x8′ plywood 3mm Birch Plywood: Ideal for Fores DIY Project

A multi-ply wood will typically be suggested if you’re looking for the most stable and 3mm birch plywood. These plywoods have inner ply thicknesses that are lower; for instance, a 1/4″ material would contain 5 plys instead of the typical 3 plys. A particular kind of core material is also typically used in multi-ply woods, with Baltic birch being the most popular choice. However, more plys are the exact opposite of what we desire when using a laser to cut delicate pieces.

Extra plys increase stability and redundancy in traditional woodwork so that if one region has a weak place, the other layers will make up for it. However, additional layers mean that there are many more potential for a poor area to occur, and just one in any layer might sabotage the cut, according to the laser.

Due to the fact that consumers would purchase a plywood with more plies if they wanted higher grade wood, this circumstance has the pernicious side effect of making standard core plywoods with fewer plies often of inferior quality.

Materials that are consistent and uniform perform best for laser cutting. Since wood is a natural product, it is not at all consistent. Due to its grain, it has imperfections like knots and voids as well as variations in density. The demands placed on the laser when creating a challenging puzzle are much higher. Everywhere, in intricate patterns that cover the entire piece, the material will be cut. Any imperfections in the wood cannot be “cut around” or avoided. A laser can only cut at one power, unlike a saw.

When it encounters a bump, it cannot accelerate faster or push harder. If, during laser-cutting, you come across a section of the material that differs significantly from the rest, you have a serious issue.The puzzle image prevents any mistakes from being redone, so if you make a mistake, the entire piece is destroyed.

Additionally, while lasers can easily cut through wood, they find it far more difficult to cut through the majority of glues. This is a concern since 3mm birch plywood is made of wood and glue sandwiched together.

3mm birch plywood Quality features

- No chipping means that the processing area won’t need to be cleaned.

- Due to contactless laser cutting, there is reduced waste and breakage.

- No need to clamp and secure plywood panels

- No tool wear, always excellent cutting quality

- high repeatability and precision

Application

- furniture

- toys

- promotional items

- bijouterie

- souvenirs

Environmental

Sourcing wood for plywood can be sustainable thanks to timber trees’ carbon sequestration and the high percentage of usable wood. On the other hand, glue raises environmental concerns as some commonly-used plywood adhesives contain toxic chemicals. However, natural-based bonding alternatives can be used to make plywood more environmentally friendly.