Description

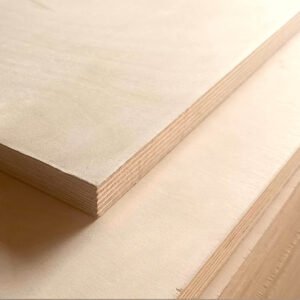

6mm Plywood Cut To Size, Birch Ply Made In China

- 6mm birch plywood that has been laser-cut produces a lot of smoke.

- Smoke stains appear on the back of the workpiece as a result of this smoke becoming trapped between the workpiece and work bed.

- A pin table raises the workpiece above the table’s base and allows for simple smoke clearance when laser cutting 6mm birch plywood sheet.

- The honeycomb work table is another efficient work surface that provides quick smoke removal.

- It has a honeycomb construction that makes it simple for smoke to pass through the cracks on the work bed’s surface.

- Additionally, if you’re looking for a laser cutter exclusively for 6mm birch plywood, it’s advised to go with the model that has the biggest work surface for the money.

- You can work on huge sheets of 6mm birch plywood board without having to cut them into tiny pieces if you have a large work area.

- Other conventional cutting methods cannot achieve the exceptional results that laser cutting plywood can, with its smooth cuts and high precision.

- However, it might provide some difficulties, so you should use caution.

- When cutting plywood with a laser, the adhesive ingredient burns with dangerous fumes, adding to the smoke already present.

- By dispersing the laser beam and staining the workpiece, this fog hampers laser cutting and lowers laser performance.

- It is impossible to completely eliminate the smoke produced when the plywood burns, but a proper exhaust system can help direct the smoke’s disposal away from the cutting area.

- Additionally, by eliminating the smoke from the workpiece while employing a pin table and high-pressure air assist, the quality of the cut can be enhanced.

6mm Birch Plywood Quality features

The lack of core gaps, a laser-compatible adhesive, and the suitable wood density are the three essential characteristics of any successful laser plywood. The 6mm birch plywood can actually be sliced well with the aid of an appropriate glue. Without it, your sheet would either start to burn or simply stop cutting, which is obviously not ideal.

Any core gap, no matter how slight, allows air bubbles to accumulate, which, when paired with laser cutting, causes them to explode and cause the wood to break. We prevent your Plywood from falling apart as soon as you receive it by ensuring that our Laserply is free of core gaps. Finally, we guarantee clean cuts by making sure our goods are the proper density. It won’t cut at all if you use a piece of plywood that is too dense, similar to what happens when you use a glue that isn’t compatible.

Application

You may create magnificent works of art out of plywood with a laser cutter, showcasing your imagination and abilities. We’ll demonstrate some laser-cut plywood projects for you to try out. Both beginners and experts may complete these projects because they are simple to follow. These ideas will motivate you to investigate the potential uses of plywood laser cutting whether you want to create something for yourself or as a present.

Environmental

6mm birch plywood can be purchased in place of raw wood to assist reduce the amount of waste produced from that source. But you must make sure that the plywood’s wood comes from responsibly managed forests. Additionally, use plywood that has no additional formaldehyde to lessen the amount of hazardous gases in the air. The most essential thing is to use plywood furniture as long as you can, upcycle it to extend its use, and make sure it is recycled completely.