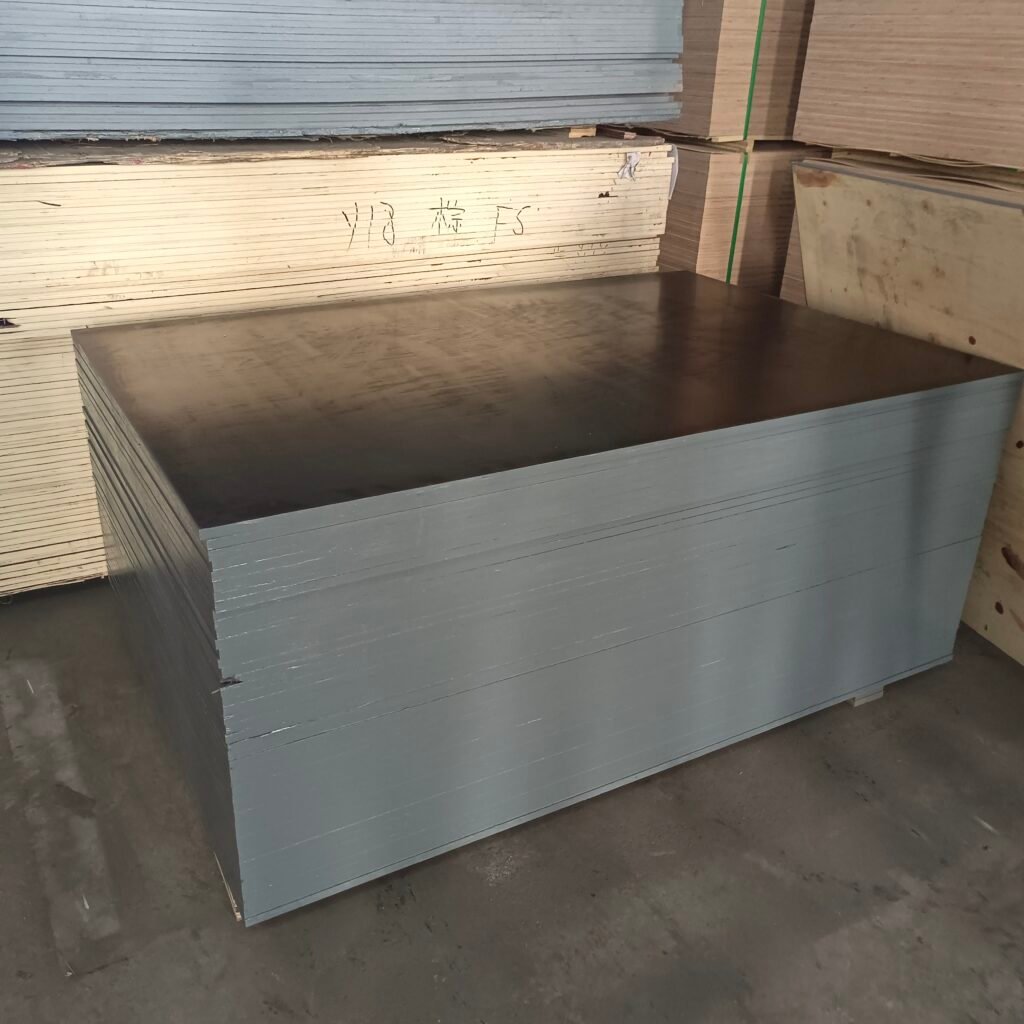

Phenolic face plywood for flight case

As a manufacturer, Foresmate Group produces high-quality plywood. Phenolic face plywood is a popular and trusted material in European countries, used to make cabinets and to build other furniture and even fixtures.

Phenolic board is an engineered material that, unlike typical plywood, uses synthetic resin as its veneer.

Contractors and builders commonly use them for residential and commercial construction. It was used to build kitchen and bathroom cabinets as well as floors.

The toughness and elasticity of phenolic panel plywood are well recognised. It can endure shock, wear, and severe handling, making it excellent for transporting valuable equipment.

Moisture resistance: Phenolic panel plywood is often coated with phenolic resin to provide good moisture resistance.

Chemical resistance:

Phenolic plywood is chemically resistant, which is an important feature in situations where equipment may be exposed to a range of substances during transportation.

High quality surface finish: The phenolic surface gives a smooth and durable surface, which can help to keep the flight case and its contents looking good.

Dimensional stability:

Under varying temperature and humidity conditions, the phenolic plywood preserves its shape and size, guaranteeing that the flight case continues to provide efficient protection.

High quality surfaces:

The Foresmate Group offers different surface textures and surface colors, which can help you choose the desired style.

Dimensional stability:

Phenolic plywood maintains its shape and size under different temperature and humidity conditions.

Foresmate offers a variety of plywood core film panels. This phenolic film has a density of 220 or 120 grams, is brown, dark brown or sometimes black, and is painted on both sides of the plywood.

All edges are sealed with acrylic paint. The edges must be resealed after cutting to protect the plywood core.

Leave a Reply