Description

Versatile BB grade 15mm Birch Plywood Made in China Factory

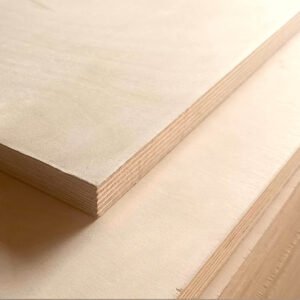

A number of wood sheets are glued together to form plywood, with the direction of the wood grain changing between the layers. There are always an odd number of plies arranged around a central plate.

15mm Birch Plywood is valued by cabinetmakers, builders, designers, artists, and craftsmen for having the following qualities: mechanical resilience (structures, buildings), flexibility (furniture), visual beauty, water resistance, and lightweight.

Laser cutting and plywood go hand in hand. With laser cutting, you can create incredibly exact shapes. With the help of a laser cutting device, plywood can be engraved to enable printing in high resolution or picture rendering. Since the laser produces precise, clean cuts, no finishing work is required.

The resilience of plywood is one of its qualities. Because it is made of several plies, it is both flexible and strong. It can be used for construction, furniture, etc. However, we need to exercise caution because the thickness of the board can make laser cutting challenging.

15mm Birch Plywood is a particularly common material for laser cutting in the arts and crafts industry. Cutting is done precisely, without any wear, and without any dust. Its use is facilitated and encouraged by flawless finishes without any post-production. Even the cutting edges’ little oxidation (browning) lends the item a specific elegance.

Temperature changes, air humidity, and light exposure can all cause wood to distort. We advise staying away from changes in temperature and humidity when using this material. Similar to unfinished wood, plywood only needs a little safeguarding. Any product for protecting wood from water or being waterproof will work. Additionally, you can varnish the plywood portion. Use a clean, soft, and lint-free cloth to clean a plywood component. You can use sandpaper and sand in the direction of the wood grain to remove embedded spots.

15mm Birch Plywood is interactively estimated and is based on a number of variables, including the quantity of material used, the amount of machine time required to cut or engrave it, and logistics expenses. As you make changes to your vector file, you can watch it evolve in real time.

15mm Birch Plywood Features

15mm Birch Plywood sheets thick will typically be the fastest, most precise, and most affordable materials for laser cutting. The process used to produce plywood may permit certain bonding faults; on occasion, the glue layer may contain minor spaces, while other times there may be an excess. With thicker plywood, more beam strength is required, more passes may be necessary, and the cut may expand and become noticeably darker. Quite frequently, it turns out that CNC milling is preferable for plywood that is thicker than 10mm. Even if they might need to be sanded in the case of plywood, advantage mill cutting bright edges are still present.

Application

- 15mm Birch Plywood For handcrafters, hobbyists, woodworkers, children, instructors, and more, it is a good source of materials.

- Craft-related thin wood sheets: With this plywood, you may make a huge range of do-it-yourself crafts, including painting, wood burning, personalized party decorations, and home decor.

Environmental

Since laser cutters are the core of our business, consumers frequently inquire with us about their environmental friendliness. 15mm Birch Plywood Laser cutters are more environmentally friendly than many conventional, manual, and mechanical methods of manufacturing in many ways, even though they do have an impact on the environment because they need electricity, gas, and fume extraction systems to be turned on and running. Let’s examine the ways in which they are superior.