Description

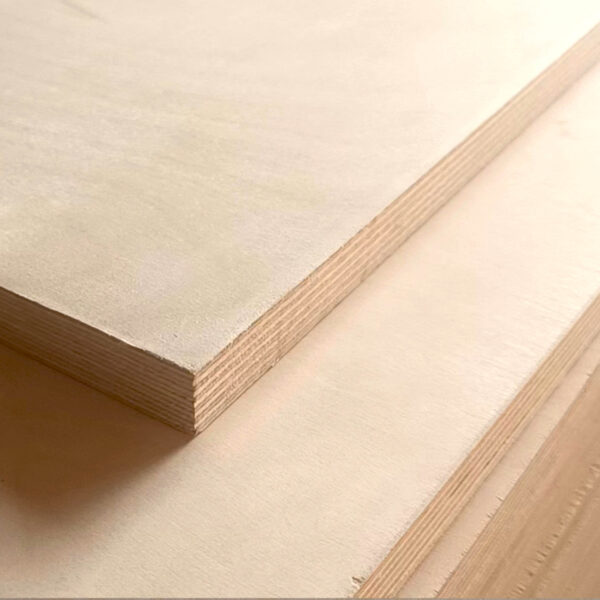

22mm Birch Plywood Cut To Size, Birch Ply Made To FORESMATE

22mm birch plywood offers a light weight and dimensional stability that make it ideal for a variety of applications, including architectural and model creation, prototyping, presents, toys, and arts and crafts. With the use of laser technology, the material may be quickly and wearlessly sliced. Laser engraving makes sure that the material’s color changes are discrete and appear realistic. Gifts or promotional goods can gain value by adding logos, names, or markings that make them unique and personalized.

Visual analysis of a variety of characteristics can reveal how some naturally occurring aspects might either be positive or inconsistent.

Straight, smooth grain and little streaking are desirable characteristics for laser engraving. You will be able to create intricate photoengraves and designs thanks to this. Due to the grain’s ability to mix into the image, details can be significantly impacted. Additionally, the ribbed sections around a tree’s center frequently provide undesirable textures that change how patterns turn out. The greater the wood grain quality, the smoother and more even it will be.

For wood-based panels, laser cutting is a great substitute for mechanical cutting techniques. The laser rapidly and effectively completes the task of straight-line cutting, figured and openwork cutting with board or plywood sheet thickness up to 10 mm. And even while the beam engraving technique is far faster than hand carving, it can match the quality of the latter.

The grade of 22mm birch plywood has an impact on the processing outcome as well. Low-grade veneer has a lot of knots, which makes it challenging to cut. However, cutting is much easier when using high-quality material, and the finished product appears much more acceptable.

22mm Birch Plywood Quality features

All of our 22mm birch plywood is guaranteed to have a surface quality of BB/BB and is made from the finest Finnish birch available. We sand the surface to 320 grit for a very smooth surface ideal for laser cutting and printing that is free of knots, spots, and discolorations. Compared to cheaper versions of Baltic ply and Lite ply, this is much stronger and of higher quality. Every piece of wood comes from Finnish forests that have received PEFC certification as sustainable.

The plywood edge that is laser cut is crisp to the touch and has a light brown color. Please be aware that when laser cutting, protective tape is always added on both sides. This tape must be removed as soon as possible.

The surface stays stain-free with the help of an optional but highly advised protective UV lacquer since it can be readily cleaned when necessary and removes dust and splinters from the wood surface, especially after removing the protective tape from the laser cutting process.

Application

Many uses for high-quality, high-strength sheet material call for the usage of 22mm birch plywood. In this sense, quality refers to resistance to warping, twisting, shrinkage, cracking, and breaking.

Exterior bonded plywood is appropriate for use outside, however since moisture affects wood’s strength, performance is best when the moisture level is kept in a relatively low range. The dimensions and strength characteristics of plywood are unaffected by sub-zero temperatures, allowing for certain unique applications.

Additionally, 22mm birch plywood is employed in stressed-skin applications as an engineering material. Since World War II, it has been employed in marine and aviation applications. The British de Havilland Mosquito bomber, which has a birch plywood body sandwiching a balsa core and heavily uses plywood for the wings, is the most known example.

In addition, the hard-chine Motor Torpedo Boats and Motor Gun Boats (MGB) made by the British Power Boat Company and Vosper, the American PT boats, and the crucial Higgins landing craft for the D-Day landings all had plywood hulls.

Because it can bend easily along the grain, 22mm birch plywood is frequently used to make curved surfaces. Plywood is frequently used as the top smooth surface over bent curves in skateboard ramps to produce transitions that can mimic the forms of ocean waves.

Environmental

Due to the additional materials needed for traditional production processes, such as lubricants and other chemicals like inks if the laser cutter is being used to engrave, additional environmental savings can be achieved. Laser cutters are unquestionably better for the environment and less expensive for the business because these extra chemicals and machine consumables are removed from the manufacturing process. This is even better for startups as it’s possible they won’t even need to purchase those extra tools and supplies.

If you are interented in our products,please feel free to contact us.