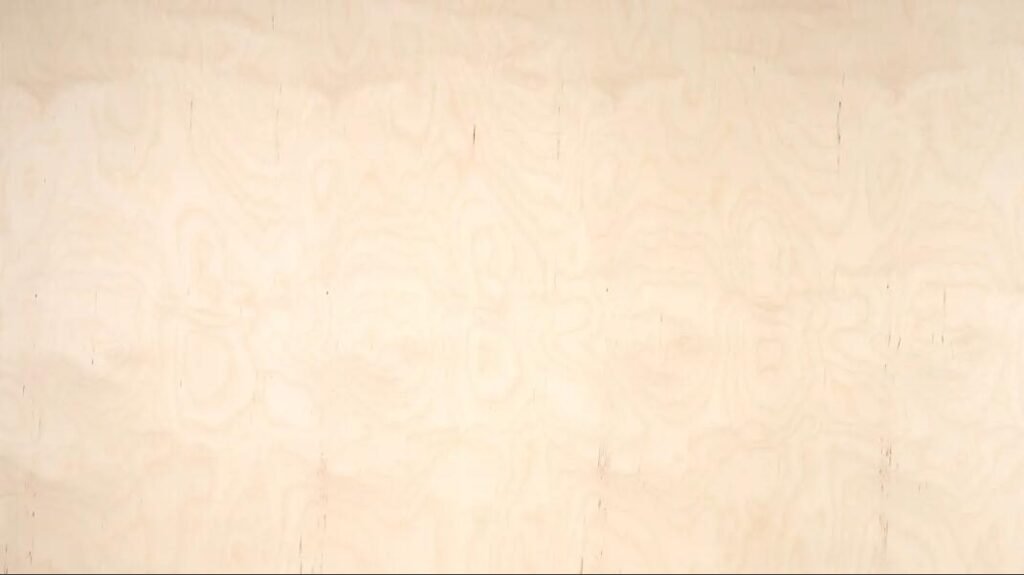

Walnut veneer

For enhancing the natural beauty and coziness of furniture, cabinets, and other woodworking projects, walnut veneer is a popular option. To acquire the quality and appearance you want, it’s crucial to take the veneer grade into account when choosing walnut veneer. The standard grading system for walnut veneer is AAA, AA, and A, with AAA being the greatest quality and A denoting the lowest.

AAA walnut veneer is the most expensive quality, and woodworkers and furniture makers greatly value it. This type of veneer frequently lacks imperfections like cracks, knots, or blemishes. Excellent quality of figure, continuous and even grain pattern, and a rich, black color. In walnut veneer, the term “figure” refers to the organic swirls, curls, and waves that may be seen in the wood grain. Because AAA grade veneer frequently has a great level of figure, it is a magnificent option for luxurious furniture and cabinetry.

Download walnut plywood catalog

Walnut plywood veneer grade catalogue

For furniture and other woodworking projects, the AA grade of walnut veneer, which is the second-highest quality grade, is a popular choice. Although AA quality veneer could occasionally have a few minuscule imperfections, such as little knots or blemishes, these are often unusual. A grain pattern that is nonetheless even and continuous is coupled with a rich hue and a medium level of figure. AA grade veneer is a fantastic alternative for furniture and cabinetry projects when a premium appearance is desired but the budget does not allow the highest grade veneer.

A grade walnut veneer is the lowest quality available, and it is frequently less expensive than AAA or AA grade veneer. This veneer grade may also have blemishes, splits, and other imperfections. More color variation and an irregular grain pattern may be seen. For applications where aesthetics aren’t as important, such interior paneling or less priced furniture, a grade veneer may still be a great choice.

When choosing a provider, it’s important to understand that the grading system for walnut veneer is arbitrary and might vary from one to another. It is a good idea to ask for a sample of the veneer to ensure that it meets your standards for quality and appearance. You can also ask for images or in-depth descriptions of any imperfections or anomalies in the veneer to help you make a decision.

The appearance and quality of walnut veneer can be influenced by a number of factors in addition to veneer grade. According to the veneer’s cut, the log is divided into thin sheets. For walnut, the two most common veneer cuts are plain sliced and rift cut. Simple sliced veneer is cut parallel to the middle of the log, which results in a more continuous and regular grain pattern. Since rift cut veneer is cut at an angle to the log’s center, it has a straighter grain pattern and less figure.

Another consideration is the thickness of the veneer. In comparison to thinner veneer, thicker veneer can be polished and sanded more regularly. Even if it costs more, thicker veneer might not be needed in every application.

To prevent breaking or cracking, walnut veneer must be handled gently. Veneer should be kept in a dry, climate-controlled area to prevent warping or cracking. When cutting or sanding veneer, use precise tools and proceed with caution to avoid splitting or tearing brought on by too much pressure.

In conclusion, walnut veneer is a wonderful and versatile material that might add warmth and character to furniture, cabinets, and other woodworking projects. It’s critical to consider the veneer’s grade in order to select walnut veneer of the finest quality.

Specifications(Panel Size)

| Thickness | 1.5mm/2mm/3mm/4mm/5mm/6mm/9mm/12mm/15mm/16mm/17mm/18mm/22mm/25mm/40mm |

| Size | 1220*2440mm/1250*2500mm/1525*1525mm |

| Faces | Walnut veneer both sides, sanded,Suitable for decorative use |

| Thickness Tolerance | ±0.2mm |

| Surface Treatment | Polished/Non-Polished |

| Moisture Content | 6%~9% |

| Density | 660-730kg/m3 |

| Glue emission level | E0, P2, WBP,MR |

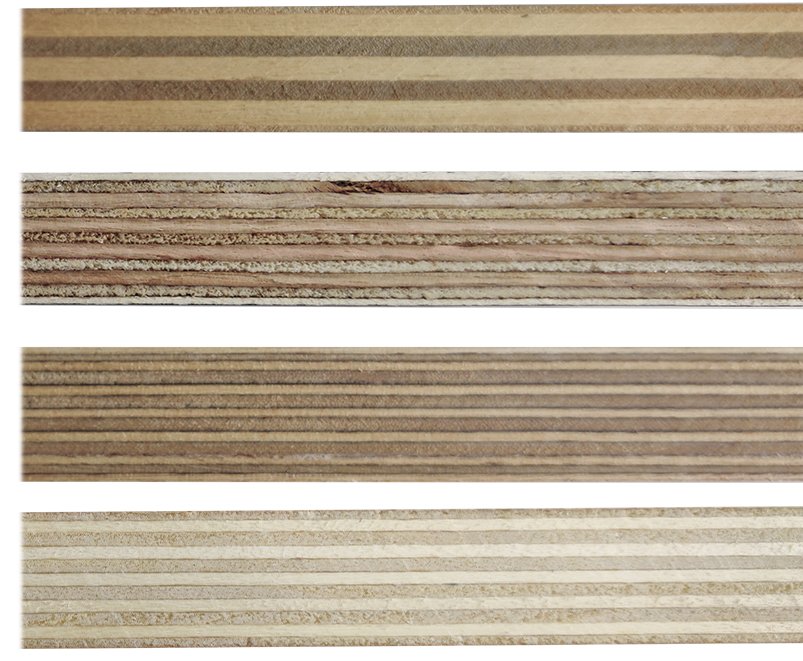

Walnut Plywood Core Construction

Thickened poplar birch core

Eucalyptus core

Birch core

Poplar core