General Veneer Core Attributes

Inner plies are made with alternating veneers. Innerply species in North America are typically softwood (fir or pine) on the west coast and poplar or aspen on the east coast. Veneer core panels are lighter than composite panels, often weighing around 70 lbs. per 3/4′′ panel. [Invalid template]

Veneer core has greater strength and stability than PBC or MDF, as well as better spanning qualities. In comparison to highly engineered PBC or MDF, veneer core has a greater range of thickness. Furthermore, with today’s thinner face veneers, this core is less forgiving; various degrees of core transfer are conceivable depending on the surface veneer or core architecture used.To avoid core telegraphing in high-end, simple sliced woods, standard or premium twostep constructions are advised.

Foresmate’s 100% veneer core products come in a variety of panel construction options to meet a variety of quality and price point requirements dictated by the application:

One-Step Procedure

Line-by-line building of 100% regional species core* (aspen, poplar, or fir, depending on your region). This traditional veneer core construction is commonly used for commodity rotary panels and works well with dark coloured commodity sliced woods like red oak or cherry. A retail/do-it-yourself favourite is standard one-step veneer core construction.

Premium Single-Step

Combination of regional species core and smooth outside crossbands chosen for uniform colour and surface smoothness next to the face and back, assembled line by line. Recommended for use with the faces of lighter-colored sliced woods, sap birch and sap rotary maple unfinished panels, as well as high-grade rotary and dark sliced UV Wood panels.

Available at an extra fee. For further information, contact Foresmate.

Typical Two-Step

Platforms made entirely of regional species core are sanded before being joined with the face and back. Pre-sanding allows two-step panels to have a narrower thickness tolerance than one-step panels. Suitable for usage with darker premium sliced wood faces, such as cherry, alder, red oak, walnut, and hickory, where colour fluctuation from outer crossbands is not an issue. It is suitable for high-quality rotary and dark-sliced UV Wood panels.

Premium Two-Step

Platforms made of the regional species core* with J-grade outside crossbands are sanded and selected for uniform colour and surface smoothness before being joined with the face and back. Two-step panels with pre-sanding provide a finer thickness tolerance than one-step panels, outperforming HPVA industry standards. Faces of lighter-colored premium sliced woods such as high-end maple, anigre, sycamore, and sap birch are suitable for use. The regularity of these premium panels guarantees that components fit well and that finish applications are consistent.

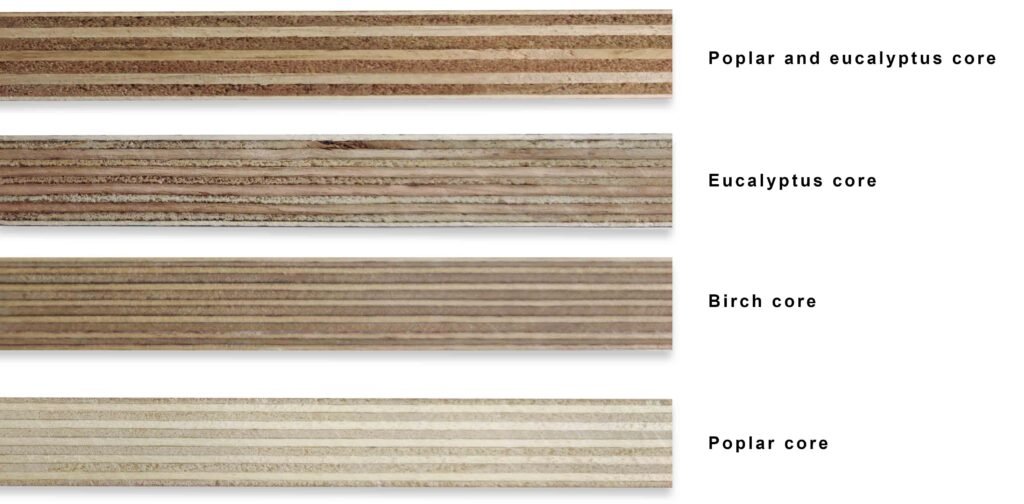

Composite and Imported Veneer Core Platforms

This is a high plycount “European style” all hardwood birch veneer core blank. This core is frequently utilised for aesthetic applications in which the panel edge is visible. Drawer sides, children’s furniture, fixture components, and other exposed core profile applications are examples of applications. Many of the multi-layered panels available today include urea formaldehyde. To ensure a no-added formaldehyde panel final product, Foresmate’s plywood sheet uses a phenolic bonded.