The Art of Wood

The underlying human urge for artistic expression mirrors our life’ reliance on the trees around us. However, the relationship between wood and art extends beyond this shared affinity.

Art can be displayed on wood…

The Granville Centre for the Arts is a non-profit organisation managed entirely by volunteers that is dedicated to creating a dynamic, accessible, and welcoming atmosphere for artistic expression. In a nutshell, The Granville Centre was founded on kindness and a desire to share art with the community. It’s no surprise that the walls of such a facility are covered in PureBond, a product manufactured by a company dedicated to “sharing the success.”

The original cinderblock walls of the center’s structure were a cold and unappealing backdrop for art when it was donated! To address this issue, founder Ryan McGuire contacted Columbia Forest Products. The walls are now covered in PureBond, a breath of fresh air that complements the art and artists.

The PureBond walls also provide an interesting backdrop for community theatre, book presentations, art workshops, poetry readings, and other events. Columbia Forest Products hopes that our presence may, in some little way, encourage good things to be experienced in this centre and community.

According to The Granville Centre for the Arts:

“From the custom door to the beautiful wall coverings, the contribution of Columbia’s PureBond panels was invaluable in turning the centre into a true work of art.”

“It’s unusual to come across a company that is so moved by the creative endeavours of a volunteer-based arts centre.” However, CFP’s passion and readiness to help our idea is impressive.”

Here are some musicians performing in the new venue.

Click to understand laser wood

Wood can be used as an artistic medium…

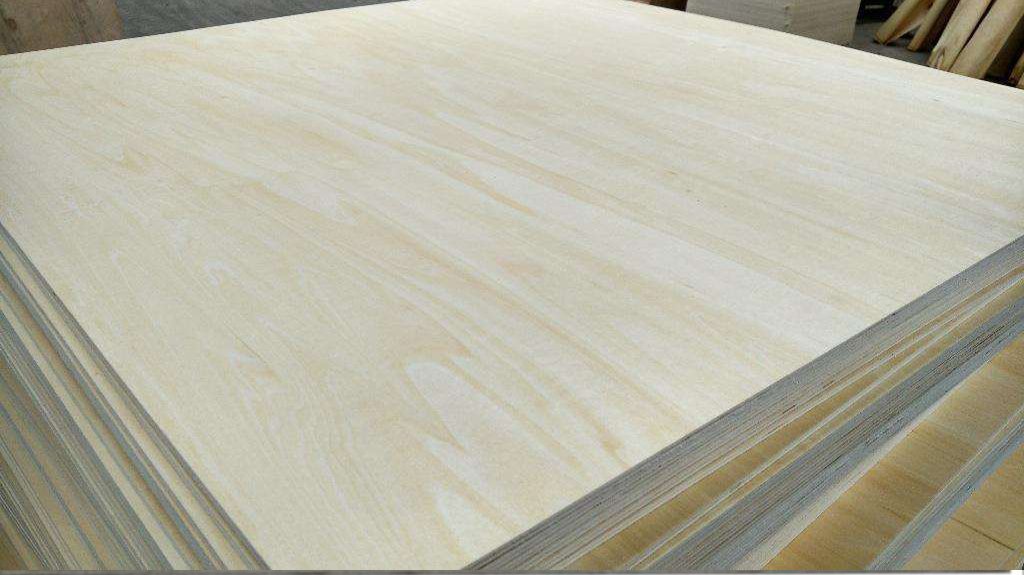

Woodblock printing is one of the oldest forms of printmaking, dating back to the second century. Lyell Castonguay is now dedicated to teaching the public about this historic skill. After working at a studio where he became known for his huge prints, Lyell created BIG INK in 2012. He initially encountered PureBond Cherry panels at that studio. “I was looking for something that was consistent, simple to use, and easy to obtain.” “There are very few voids, and the material quality is very consistent,” he remarked.

Lyell continues to use and suggest Cherry PureBond plywood due to its distinct grain pattern and depth of layers. It also links him to the early woodblock printmakers, who employed solid Cherry blocks. Workshop registrants labour on their wood carvings for months before BIG INK arrives with their iconic BIG Tuna printing press to put it all together. They hold 18 workshops every year, and each participant receives tools, online training, and a sample of PureBond to practise on before carving on full-sized sheets.

That’s right: each attendee prints on at least a 24-inch × 46-inch panel, with some going as large as 40 inches x 96 inches. When asked why he used such a large format, Lyell explained, “It’s the physicality of the process.” I’m a big fan of delayed gratification. It truly takes hours and hours to carve.” He went on to say, “The bigger the piece, the bigger the wow factor.”

This is how it’s done.

His words of wisdom for everyone interested in woodblock printing? Take the risk and give it a shot. “It can be a little nerve-racking, but part of the process is accepting that it will always turn out differently than you expect.” It would be a lot less fun if you knew exactly how it was going to end out.” Lyell remarked that most people can do woodblock printing because it simply requires ink, wood, simple carving tools, and paper.

Register for a BIG INK workshop here. Lyell also hopes to launch a totally online programme in July, allowing beginners to learn on smaller pieces of wood and print at home.

Wood has the potential to be ART…

Cory Bonnet never anticipated that 20 years later, he’d be creating art and preserving artefacts related to the steel industry while working in hardwood plywood distribution.

He was initially introduced to PureBond as a painting medium in 2006, and he was able to access it readily due to his status. Cory still employs PureBond in his artwork nearly two decades and an enormous artefact collection afterwards.

Cory acquired a massive amount of foundry designs, moulds, and equipment related to the steel industry from the late 1800s and early 1900s in June 2021. Cory has worked relentlessly since then to show, protect, and utilise this windfall of history. This prompted him to establish Patterns of Meaning, a 10,000-square-foot studio in downtown Pittsburgh devoted to conveying the tales of the people who founded America.

There, he creates works of art that honour these artefacts and the steelworkers’ past, many of which are painted on PureBond panels. “The birch and maple plywood, with their grain and wave, make it such a good surface to work with,” remarked Cory.

The Art of Wood

In fact, Cory sees the wood as more than just a medium, but as a guide for the piece’s flow. “The paint adheres to the wood, allowing some of the grain to show through.” I let the grain influence a lot of the painting’s direction. “I like it because it adds details that I don’t have to make,” he said. “I’m pulling things out of the panel instead of building up like I would on a fabric canvas.” The paint and pigments are magically drawn out of the substrate. I don’t have to think about it; all I have to do is enjoy seeing it appear.”