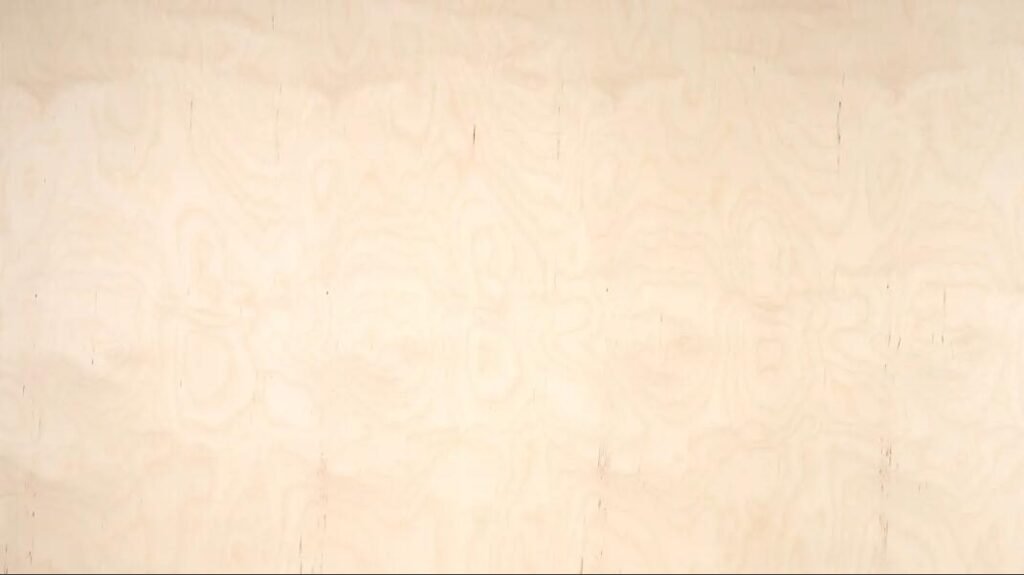

CP birch veneer

CP birch veneer: Face and back in one piece. Face and back grade veneers provide an unlimited number of sound knots, split repairs, and patches. The panel is made for laminating and is sound on both sides. Patches, visible knots, and minor veneer breaks are permitted.

Face and back are one piece. Face and back grade veneers provide an unlimited number of sound knots, split repairs, and patches. The panel is laminate-ready and sound on both sides.

Due to the CP birch veneer’s lack of limitations. Since the front and back are made of a single piece, they can be divided, repaired, patched, and knotted indefinitely. The front and back of the document are both clear and made for lamination.

This is a step down from BB with more facial patches that might not always be color-matched. Splits no larger than 0.5 mm are permitted.

Download CP birch plywood catalog

CP Birch plywood veneer grade catalogue

CP garde birch veneer

Because it is the greatest option in terms of quality, birch plywood is the most widely used variety of plywood board for indoor use. In comparison to poplar plywood, it has a clearer wood grain and comes equipped with waterproof glue. Additionally, birch is a species of hardwood. The softwood poplar is more softer than this plywood panel. Therefore, it can withstand being hit. This increases the material’s toughness as well.

Birch plywood has neat, ornamental edges and a natural, light-brown color. Birch plywood displays the wood’s distinct grain, which gives the material its gritty flames. The plywood is uniformly drawn with the wood grain along its whole length. For horizontal uses like flooring and window sills, our plywood panels are appropriate. Consider the possibility of warping when applying to vertical applications.

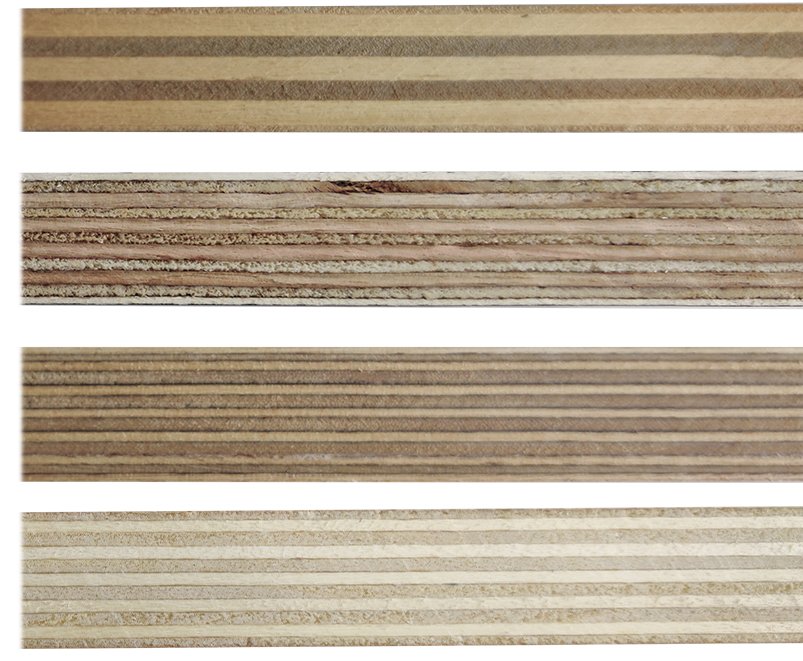

Birch veneer is layered to create plywood made of birch. Crosswise adhesive is used to join these layers. As a result, the board becomes stable. Despite this, the glued wood is still present. When birch plywood is being sawed and processed, tension can be released, which can lead to longer sheets bending.

Combinations of letters can be used to determine the plywood’s quality. There is a letter designation for the front (top side) and a different one for the back (bottom side). This is referring to the veneer quality; the glue quality, for instance, is represented in a different way. A typical quality that can be utilized in decorative applications is BB. The quality of the visible side is denoted by the first letter, in this case CP, while the quality of the reverse side is denoted by the second letter, in this CP birch veneer.

The visible side of this board’s material is CP. Each side has the CP visual quality, top and lower. Defects have been filled and knots have disappeared in CP birch veneer. Additionally, (big) discolorations, technical flaws, and veneer cracks are permitted. CP birch veneer plywood is of poor quality and ought to only be used for building projects.

If you have sharp tools, working with plywood is a simple task. We advise using a wood drill with a center point for drilling holes. Additionally advised for this panel material is pre-drilling. Finish the board with a (clear) varnish, stain, or paint because the material can fade over time. Finish the edges of plywood with an edge sealer to avoid varnish or stain penetrating the board material, which could cause the veneer layers to come loose.

Specifications(Panel Size)

| Thickness | 1.5mm/2mm/3mm/4mm/5mm/6mm/9mm/12mm/15mm/16mm/17mm/18mm/22mm/25mm/40mm |

| Size | 1220*2440mm/1250*2500mm/1525*1525mm |

| Faces | CP birch veneer both sides, sanded,Suitable for decorative use |

| Thickness Tolerance | ±0.2mm |

| Surface Treatment | Polished/Non-Polished |

| Moisture Content | 6%~9% |

| Density | 660-730kg/m3 |

| Glue emission level | E0, P2, WBP,MR |

Birch Plywood Core Construction

Thickened poplar birch core

Eucalyptus core

Birch core

Poplar core